Week Fifteen: Final Project Submission

Meet TelIoT: The Toilet Paper Revolution

Pitch

This project originated with the fact that on the first week of class we were asked to think of ideas for a final project. After a long time of thinking it finally hit me - as deep thinkers, where and when do we think the most productively? Even Archimedes came up with his work in the bathtub.

Meet LetIoT - the toilet paper revolution.

LetIoT is an IoT-enabled toilet paper dispenser. It allows you to control your dispensing features near and far, electronically, and know in advance, precisely, when you are about to run out of paper; no more “surprises” just as you’re about to run out!

Background

Project progress throughout the semester is documented in the Week One link. Overall I took a modular approach, with building a new part relevant to my final project during most (but not all) weeks. Below I’ll describe the final projects so that it is easily reproducible, from the 3 main aspects of making: Hardware, Software and Enclosure.

Hardware

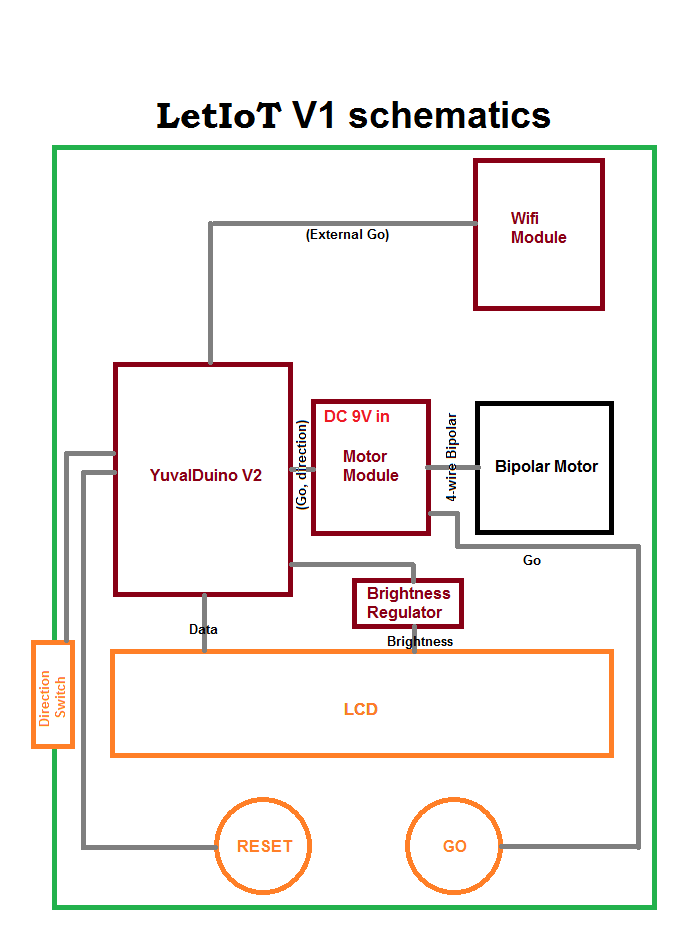

Here’s an image describing the main modules:

The board is made out of 4 main PCBs:

Core - Fabduino

Most instructions pass through this module (shortage in pins made me have to do some surgery, otherwise ideally this would serve has the hub in a hub-and-spoke topology).

Details on how to make the Fabduino are described in the Input Devices Week page, including specific installation instructions, a board file, pinout and other important data. Minor changes were made in the V2 version milled for this project, most importantly the removal of both temperature sensors for the sake of more pins.

The module is connected to the LCD display and is used to store data and provide instructions to the peripherals.

Motor Module

This module operates two H-Bridges that run the bipolar 4-wire motor. The two main parameters this module accepts as inputs are the Go instruction and the Direction instruction (rotate clockwise or counterclockwise).

Details on how to make this module are described in the Output Devices Week page, including specific installation instructions, other hackables, pinout and other important data. Very minor changes were made in the V2 version milled for this project, most importantly connecting more pins in the ATTINY-44 to the outside world to allow for more modularity.

LCD with voltage converter

The LCD displays the direction control, as well as number of rotations made so far since the last replacement, and the device’s IP address.

In a basic configuration, 10 wires are enough to operate the LCD: 6 data pins, and 4 pins to control the brightness of the screen. A small breakout board does just that. Details on connectivity and this module are also described in the Output Devices Week page. This board was left unchanged for the final project:

Wifi Module

The Wifi Module is a ESP-8266 board that is used as a network server. It allows control over lighting and external dispensing.

Ideally, the wifi module would have a serial connection to the main fabduino. I tried to work on this for several hours but couldn’t get the handshake right (baud rate) so for now am doing a bypass through a host computer.

Details on connectivity and this module are also described in the Networking Week page, including my endless struggle with AT vs. NodeMCU, reflashing the device and other issues. This board was left unchanged for the final project:

Other

A smaller PCB (not described in above image) converts a 9V coaxial input to a 6-pin FTDI interface (just for the sake of the connector):

For the switch, I used a generic Radio Shack switch we had at the lab. The two buttons were purchased from Amazon.

Software

Code for Fabduino

See below for the fabduino code, which is also downloadable here. More details about LCD connectivity and button debouncer are in the Input Devices Week page. For this project, I added support for direction pin (which is then routed to the motor module and displayed via the lcd), as well as serial connection support for the host to display the IP address the Wifi module has acquired.

#include <LiquidCrystal.h>

#include <SoftwareSerial.h>

/*

LetIoT

For use with Yuvalduino

Yuval Gonczarowski

HTMAA

December 2016

RS = My 5, LCD 4

LCD E = My 7, LCD 6

D4 = My 10, LCD 11

D5 = My 9, LCD 12

D6 = My 8, LCD 13

D7 = My 6, LCD 14

R/W = GND LCD 5

VSS = GND

VCC = 5V

Wiper to LCD V0

*/

int Dir_In_Pin = 4;

int Dir_Out_Pin = 3;

//int LEDPin = 13;

int externalGoIn = 13;

int externalGoOut = 12;

int RotateButtonPin = 11;

int numRotations = 0;

int iter = 0;

int current_stateBtn;

int last_stateBtn;

int current_ex;

int last_ex;

char myip[15];

int myipindex = 0;

char incomingByte = 0; // for incoming serial data

unsigned long lastDebounceTimeBtn = 0; // the last time the output pin was toggled

unsigned long lastDebounceTimeEx = 0; // the last time the output pin was toggled

unsigned long debounceDelayBtn = 20; // the debounce time; increase if the output flickers

unsigned long debounceDelayEx = 20; // the debounce time; increase if the output flickers

LiquidCrystal lcd(5, 7, 10, 9, 8, 6);

// the setup function runs once when you press reset or power the board

void setup() {

lcd.begin(16, 2);

lcd.print("Searching IP...");

Serial.begin(9600);

Serial.write("Welcome, Debugger!");

// initialize digital pin LED_BUILTIN as an output.

// pinMode(LEDPin, OUTPUT);

pinMode(RotateButtonPin, INPUT);

pinMode(Dir_In_Pin, INPUT);

pinMode(externalGoIn, INPUT);

pinMode(externalGoOut, OUTPUT);

pinMode(Dir_Out_Pin, OUTPUT);

current_stateBtn = digitalRead(RotateButtonPin);

last_stateBtn = current_stateBtn;

current_ex = digitalRead(externalGoIn);

last_ex = current_ex;

}

int GoHandler(unsigned long* LDT, unsigned long* DD, int* current, int* last, int pin)

{

int reading = digitalRead(pin);

if (*last != reading) {

*LDT = millis();

}

if ((millis() - *LDT) > *DD) {

// whatever the reading is at, it's been there for longer

// than the debounce delay, so take it as the actual current state:

// if the button state has changed:

if (reading != *current) {

*current = reading;

// only toggle the LED if the new button state is HIGH

if (*current == LOW) {

++numRotations;

}

}

}

*last = reading;

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(externalGoOut, digitalRead(externalGoIn));

// digitalWrite(LEDPin, HIGH);

delay(10);

// digitalWrite(LEDPin, LOW);

delay(10);

GoHandler(&lastDebounceTimeBtn, &debounceDelayBtn, ¤t_stateBtn, &last_stateBtn, RotateButtonPin);

GoHandler(&lastDebounceTimeEx, &debounceDelayEx, ¤t_ex, &last_ex, externalGoIn);

lcd.setCursor(0, 1);

lcd.print(numRotations);

lcd.setCursor(12,1);

if (digitalRead(Dir_In_Pin) == HIGH) {

lcd.print("CW ");

digitalWrite(Dir_Out_Pin, HIGH);

}

else {

lcd.print("CCW");

digitalWrite(Dir_Out_Pin, LOW);

}

// Loop runs every 20 ms. Every 10 seconds - refresh IP address

if (iter == 500) {

while (Serial.available() > 0) {

incomingByte = Serial.read();

if (((incomingByte >= '0') && (incomingByte <= '9')) || (incomingByte == '.')) {

myip[myipindex++] = incomingByte;

}

} // say what you got:

if (myipindex > 0) {

while (myipindex < 16){

myip[myipindex++] = ' ';

}

}

lcd.setCursor(0, 0);

Serial.println(myip);

lcd.print(myip);

myipindex = 0;

iter = 0;

}

iter++;

}

Code for Wifi Module

The Wifi module code was written in Lua (again, on my struggles with Lua, see the Networking Week page, including instructions how to install esplorer and reflash the device. The init.lua file can be downloaded here (remember to rename to init.lua for automatic load-on-reset). For the sake of final project demonstration, I purchased a $15 router and named it HTMAA_Yuval with the password described below.

wifi.setmode(wifi.STATION)

wifi.sta.config("HTMAA_Yuval","fablab123")

print(wifi.sta.getip())

NumUses=0

if srv~=nil then

srv:close()

end

led1 = 7

externalGo = 0

gnd_led = 6

vcc_led = 5

gpio.mode(led1, gpio.OUTPUT)

gpio.mode(externalGo, gpio.OUTPUT)

gpio.mode(gnd_led, gpio.OUTPUT)

gpio.mode(vcc_led, gpio.OUTPUT)

gpio.write(externalGo, gpio.LOW)

gpio.write(gnd_led, gpio.LOW)

gpio.write(vcc_led, gpio.LOW)

srv=net.createServer(net.TCP)

srv:listen(80,function(conn)

conn:on("receive", function(client,request)

local buf = "";

local _, _, method, path, vars = string.find(request, "([A-Z]+) (.+)?(.+) HTTP");

if(method == nil)then

_, _, method, path = string.find(request, "([A-Z]+) (.+) HTTP");

end

local _GET = {}

if (vars ~= nil)then

for k, v in string.gmatch(vars, "(%w+)=(%w+)&*") do

_GET[k] = v

end

end

buf = buf.."<h1> eToiler ePaper eDispenser</h1>";

buf = buf.."<p>My IP is ";

buf = buf..tostring(wifi.sta.getip());

buf = buf.."</p>";

buf = buf.."<p>Number times used since last reset: ";

buf = buf..tostring(NumUses);

buf = buf.."</p>"

buf = buf.."<p> Get more on <a href=\"https://www.amazon.com/s/ref=nb_sb_noss?url=search-alias%3Daps&field-keywords=Toilet+Paper\">Amazon</a> </p>";

buf = buf.."<p>Light: <a href=\"?pin=ON1\"><button>ON</button></a> <a href=\"?pin=OFF1\"><button>OFF</button></a></p>";

buf = buf.."<p>Dispense: <a href=\"?pin=GO1\"><button>GO</button></a> </p>";

local _on,_off = "",""

if(_GET.pin == "ON1")then

gpio.write(led1, gpio.HIGH);

gpio.write(vcc_led, gpio.HIGH);

elseif(_GET.pin == "OFF1")then

gpio.write(led1, gpio.LOW);

gpio.write(vcc_led, gpio.LOW);

elseif(_GET.pin == "GO1")then

gpio.write(led1, gpio.HIGH);

gpio.write(externalGo, gpio.HIGH);

tmr.delay(2000000);

gpio.write(led1, gpio.LOW);

gpio.write(externalGo, gpio.LOW);

end

client:send(buf);

client:close();

collectgarbage();

end)

end)

Code for Motor Module

The code for the ATTINY44 that runs the motor module is heavily based on Neil’s Hello World Bipolar example, with a few minor changes:

-

The button press command has moved to an interrupt handler

-

Support for external direction rotation was added

-

and another external go bit handler was added in the main loop.

Links to download followed by the code itself:

//

//

// hello.stepper.bipolar.44.full.c

//

// bipolar stepper mode for Yuval's TP Project

// Yuval Gonczarowski 12/15/16

//

// Based on Hello World Bipolar stepper by

// Neil Gershenfeld

// 11/21/12

//

// (c) Massachusetts Institute of Technology 2012

// This work may be reproduced, modified, distributed,

// performed, and displayed for any purpose. Copyright is

// retained and must be preserved. The work is provided

// as is; no warranty is provided, and users accept all

// liability.

//

#include <avr/io.h>

#include <util/delay.h>

#include <avr/interrupt.h>

#include <avr/pgmspace.h>

#define output(directions,pin) (directions |= pin) // set port direction for output

#define set(port,pin) (port |= pin) // set port pin

#define clear(port,pin) (port &= (~pin)) // clear port pin

#define pin_test(pins,pin) (pins & pin) // test for port pin

#define bit_test(byte,bit) (byte & (1 << bit)) // test for bit set

#define bridge_port PORTA // H-bridge port

#define bridge_direction DDRA // H-bridge direction

#define A2 (1 << PA0) // H-bridge output pins

#define A1 (1 << PA1) // "

#define B2 (1 << PA3) // "

#define B1 (1 << PA4) // "

#define button_pressed() ((!(PINA >> 7) & 1))

#define direction_ccw_set() ((PINB >> 1) & 1)

#define external_go() (PINB >> 2)

#define on_delay() _delay_us(25) // PWM on time

#define off_delay() _delay_us(5) // PWM off time

#define long_delay() _delay_ms(2000) // Long delay between external go busy-wait

#define PWM_count 100 // number of PWM cycles

#define step_count 5 // number of steps

void set_button_interrupt();

void step_cw();

void step_ccw();

void go(uint8_t dir);

static uint8_t count;

static uint8_t went_counter;

ISR(PCINT0_vect) {

//

// pin change interrupt handler

//

if (!button_pressed()) { // avoid interrupt on both push and release

set_button_interrupt();

return;

}

go(direction_ccw_set());

set_button_interrupt();

}

void go(uint8_t dir)

{

static uint8_t i, j;

for (i = 0; i < step_count; ++i) {

if (dir) {

for (j = 0; j < i; ++j)

step_cw();

}

else {

for (j = 0; j < i; ++j)

step_ccw();

}

}

}

void set_button_interrupt()

{

//PA7 = PCINT10

// Set GIMSK pin PCIE0 to high to enable PCINT[7:0]

set(GIMSK, 1 << PCIE0);

set(PCMSK0, 1 << PCINT7);

sei();

}

//

// A+ B+ PWM pulse

//

void pulse_ApBp() {

clear(bridge_port, A2);

clear(bridge_port, B2);

set(bridge_port, A1);

set(bridge_port, B1);

for (count = 0; count < PWM_count; ++count) {

set(bridge_port, A1);

set(bridge_port, B1);

on_delay();

clear(bridge_port, A1);

clear(bridge_port, B1);

off_delay();

}

}

//

// A+ B- PWM pulse

//

void pulse_ApBm() {

clear(bridge_port, A2);

clear(bridge_port, B1);

set(bridge_port, A1);

set(bridge_port, B2);

for (count = 0; count < PWM_count; ++count) {

set(bridge_port, A1);

set(bridge_port, B2);

on_delay();

clear(bridge_port, A1);

clear(bridge_port, B2);

off_delay();

}

}

//

// A- B+ PWM pulse

//

void pulse_AmBp() {

clear(bridge_port, A1);

clear(bridge_port, B2);

set(bridge_port, A2);

set(bridge_port, B1);

for (count = 0; count < PWM_count; ++count) {

set(bridge_port, A2);

set(bridge_port, B1);

on_delay();

clear(bridge_port, A2);

clear(bridge_port, B1);

off_delay();

}

}

//

// A- B- PWM pulse

//

void pulse_AmBm() {

clear(bridge_port, A1);

clear(bridge_port, B1);

set(bridge_port, A2);

set(bridge_port, B2);

for (count = 0; count < PWM_count; ++count) {

set(bridge_port, A2);

set(bridge_port, B2);

on_delay();

clear(bridge_port, A2);

clear(bridge_port, B2);

off_delay();

}

}

//

// clockwise step

//

void step_cw() {

pulse_ApBp();

pulse_AmBp();

pulse_AmBm();

pulse_ApBm();

}

//

// counter-clockwise step

//

void step_ccw() {

pulse_ApBm();

pulse_AmBm();

pulse_AmBp();

pulse_ApBp();

}

int main(void) {

//

// main

//

//

// set clock divider to /1

//

CLKPR = (1 << CLKPCE);

CLKPR = (0 << CLKPS3) | (0 << CLKPS2) | (0 << CLKPS1) | (0 << CLKPS0);

//

// initialize bridge pins

//

clear(bridge_port, A1);

output(bridge_direction, A1);

clear(bridge_port, A2);

output(bridge_direction, A2);

clear(bridge_port, B1);

output(bridge_direction, B1);

clear(bridge_port, B2);

output(bridge_direction, B2);

//

// main loop

set_button_interrupt();

went_counter = 0;

//

while (1) {

if (external_go())

{

go(direction_ccw_set());

go(direction_ccw_set());

go(direction_ccw_set());

long_delay();

}

}

}

Serial host bypass

My original intention was to connect the TX and RX of the Wifi module to two pins on the fabduino, using the SoftwareSerial library, in an effort to transfer the IP address to the LCD screen after it is acquired.

I found the Software serial package to be unreliable - it kept going out of sync despite several efforts to make the process more efficient and use a very low baud rate. Giving up, I ended up using a bypass with a host computer. This code is to be run every time reset is pushed, to enable the above feature (download):

#!/usr/bin/python

import sys

import serial

import time

portwifi = "/dev/tty.usbserial-FT9KZ5BU"

speedwifi = 115200

portfab = "/dev/tty.usbserial-FT94TLAR"

speedfab = 9600

ser_wifi = serial.Serial(portwifi, speedwifi)

ser_wifi.setDTR()

ser_fab = serial.Serial(portfab, speedfab)

ser_fab.setDTR()

time.sleep(5)

ser_wifi.flushInput()

ser_wifi.flushOutput()

ser_wifi.write(b'=wifi.sta.getip()\r\n')

time.sleep(1) # wait a sec

myip = ""

while (ser_wifi.inWaiting()):

byte = ser_wifi.read();

myip += byte

sys.stdout.write(byte);

sys.stdout.write('\n')

myip = myip.split( )[1].split(' ')[0]

print myip

ser_fab.write(myip+'\r\n')

entered = 0

while(1):

while (ser_fab.inWaiting()):

byte = ser_fab.read();

sys.stdout.write(byte);

entered = 1;

time.sleep(0.1) # wait a bit

if (entered):

sys.stdout.write('\n')

entered = 0;

Design and enclosure

Box

The box was milled on a Shopbot using vCarve. My original intention was to 3rd print the box, but this ended up being a 17-hour job which would be too long (lesson learned: don’t to it in the last week). So after I sent the print I went ahead and milled the box on the shopbot - it actually looked pretty nice so I went with that.

Here’s (3dm, stl) the 3D model of the box.

For vCarve, I used a 2D flat model of the 5 sides (useful Rhino commands: DupEdgeMesh and Explode) and milled it on a nice piece of wood we had. Download DXF

Modelo:

Box By Yuval Gonczarowski Modelo »

Roller

The Roller was 3D printed, with a precise diameter to fit the connector used on the motor, and room for two screws.

Here’s (3dm, stl) the 3D model of the roller.

The printer of choice was the 3D Wox, because it was available and because I haven’t used it thus far. Printing was literally as easy as pushing a button. Supports were fairly easy to remove.

Modelo:

Roller By Yuval Gonczarowski Modelo »

Other Side Holder

The holder on the other side is detachable, allowing the user to replace the toilet paper roll when finished. My original thought (as described in the week 1 page) was to use a spring for this, but I ended up using press-fit with a simple puzzle piece design, copied from my efforts during 3D Printing week.

Here’s the 2D flattened DXF Model: Download DXF

I used a nice piece of wood found at the lab. Lessons from here include paying special attention to milling from outside/inside (made that mistake once) and profile/pocket toolpaths. Also, never trust others! The 0.125” endmill was defined in vCarve to have a 0.25” diameter. Argh!

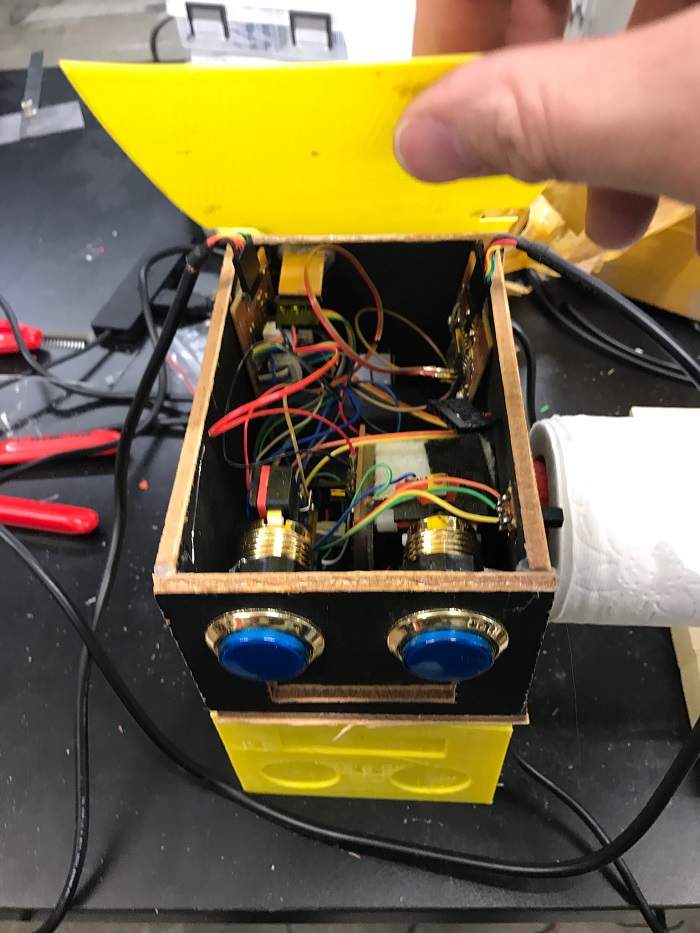

Velcro

Lastly, order inside the box is extremely important, especially given the large amount of wires (as a result of the modular build). I used small pieces of velcro to make sure nothing remains “floating” inside the box.

Photos

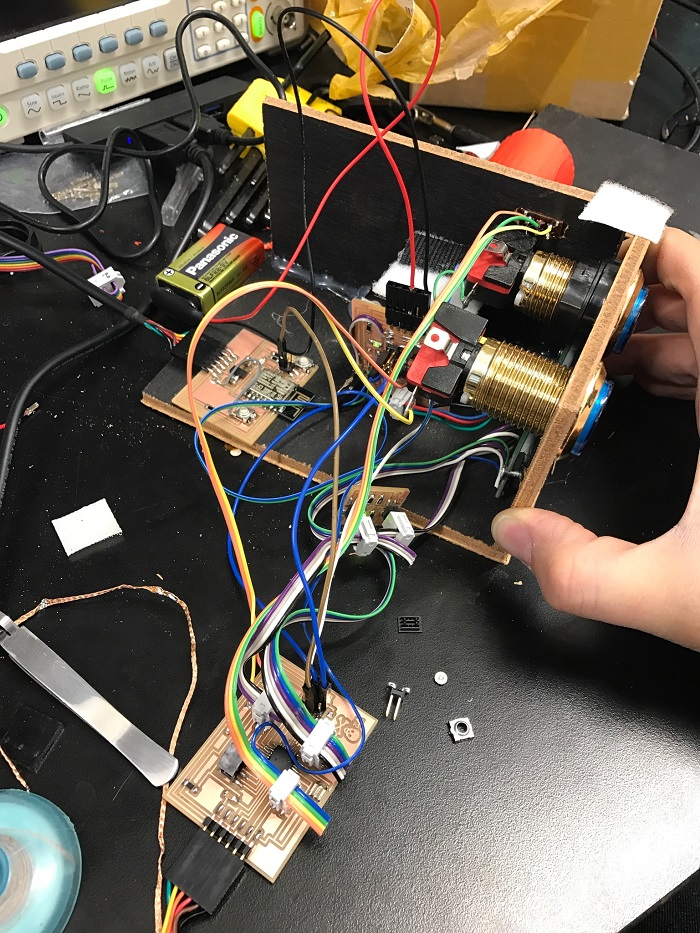

Connecting things:

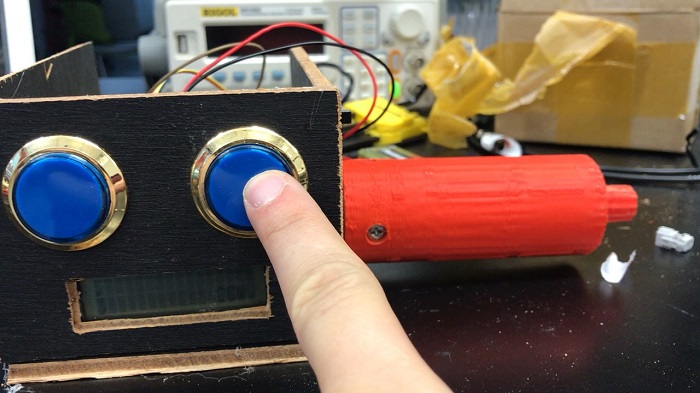

Push the button:

About to wrap it all up::

Yuval and a friend: